EDI MCS or EDI Mission Critical Support is a one stop technical helpdesk for global EDI users. The purpose of EDI MCS is to understand and provide knowledge based technical support to EDI users arising out of issues related to EDI GAP Analysis, EDI Map development, Trading Partner setup, EDI Map Translation, Testing in the staging and production environment. It’s a Value Added Service (VAS) provided by Crossroad which goes beyond the scope of standard support offerings.

Crossroad aims to provide this service through its EDI MCS portal. The target audience of the MCS service includes EDI professionals, Consulting companies who provide EDI services to its customers and EDI end users which includes corporate in the retail, automobile, electronics, pharmaceutical and manufacturing business.

For more information on Crossroad EDI MCS visit our MCS portal click here.

Thursday, February 19, 2009

Friday, January 9, 2009

Common Methods of Shipment requested by the Retailer

The complex way of transportation, at times, makes delivery processing very cumbersome. Many a times it raises logistical intricacy with transporter or the supplying vendor. The shipment manifest or the shipping consignment should carry proper marking details including dispatch sequence. This process gets even more complicated when the Retailer wants abnormal dispatch sequencing. To cater these requirements, we use particular segment or set of segments to facilitate during EDI transmission. While transmission of such data we have to keep in mind whether the VAN’s EDI support system can handle the complex scenario properly or not. Through our experience we have found that faulty support created transmission bottleneck and improper routing sequence.

The most used shipment methods with x12 data samples are given below :

Basic Shipment

Basic orders when a quantity of product is ordered without specific mention of which store location is to ultimately receive the merchandise. The entire lot is shipped to the distribution facility and will be distributed to the various stores as needed. A Basic Purchase Order can be identified by an occurrence of the header level N1 segment with a “BY” qualifier in N101 to specify the buying party, and the absence of an SDQ segment in the Detail Segment of the Order. The N1 Segment will identity the distribution facility location issued in the Global Location Number format.

ISA*00* *00* *12*9086880888T *12*to be filled up len 15*060525*1248*U*00401*000000166*0*P*>

GS*PO*9086880888T*to be filled up*20060607*1248*1*X*004010

ST*850*10002

BEG*00*SA*DH48130**20050406

REF*IA*6 digit vendor#

CSH*SC

SAC*A*E750****3*5**ZZ*0*30

DTM*001* 20050701

DTM*010* 20050609

N1*BY*SCHAUMBURG*92* 0145

PO1**24*EA*3.78**UP*081492463009

PO1**48*EA*1.2**UP*081492389002

PO1**36*EA*2.79**UP*081492462392

CTT*3

SE*13*10002

GE*1*1

IEA*1*000000166

Spreadsheet Shipment

Spreadsheet Orders are those in which the product is ordered for multiple store location and shipped directly to those store locations. A Spreadsheet Purchase Order can be identified by an occurrence of a header level N1 segment with a “FR” qualifier in N101, and the presence of an SDQ found in the Detail section of the Purchase Order that specifies the various Store Numbers in the Global Location Number format.

ISA*00* *00* *12*9732397773T *12*to be filled up len 15*060525*1248*U*00401*000000170*0*P*>

GS*PO*9732397773T*to be filled up*20060607*1248*1*X*004010

ST*850*10003

BEG*00*SA*DX45902**20050614

REF*IA*6 digit vendor#

DTM*001* 20050722

DTM*010* 20050630

N1*FR*Ferari*92* 0145

PO1**600*EA*6.5**UP*053124549801

SDQ*EA*92*0008*120*0020*180*0023*60*0024*60*0025*90*0026*90

PO1**400*EA*2.6**UP*053124549818

SDQ*EA*92*0008*80*0020*120*0023*40*0024*40*0025*60*0026*60

PO1**250*EA*3.9**UP*053124549788

SDQ*EA*92*0008*50*0020*75*0023*24*0024*25*0025*38*0026*38

CTT*3

SE*14*10003

GE*1*1

IEA*1*000000170

Cross-Dock Shipment

Cross-Dock orders are used when the product ordered is pre-sorted by the vendor by store location, but shipped to a distribution facility rather than to a store location. A Cross-Dock Purchase Order can be identified by having an N1 Segment with ST in N101 and the SDQ Segment listing the store locations in the detail

ISA*00* *00* *01*245588694*01*VENDORDUNS*060525*1248*U*00401*000000001*0*T*>

GS*PO*245588694*VENDORDUNS*20060525*1248*1*X*004010

ST*850*0001

BEG*00*SA*COSTCO001**20060525

REF*VR*VEN01

REF*DP*C001*COSTCO DEPARTMENT

REF*19*C9*COSTCO REGION

REF*ZZ*COSTCOV999*COSTCO BUYER VENDOR NUMBER

FOB**ZZ*LOCATION DESCRIPTION

SAC*A*ZZZZ***990*******02***ALLOWANCE DESCRIPTION

ITD***3*20060601********TERMS OF SALES DESCRIPTION

DTM*175*20060725

DTM*002*20060620

DTM*010*20060613

TD5*****ROUTING INSTRUCTION

N9*H7*SPECIAL INSTRUCTION

MSG*SPECIAL INSTRUCTION TEXT

MSG*SPECIAL INSTRUCTION TEXT

MSG*SPECIAL INSTRUCTION TEXT

N9*H5*LEGAL DISCLAIMER

MSG*LEGAL DISCLAIMER TEXT

MSG*LEGAL DISCLAIMER TEXT

MSG*LEGAL DISCLAIMER TEXT

N1*ST*COSTCO WH CN*9*2455886942222

N3*112 ABC 1# LANE

N4*VANCUVER*VA*9988528

PER*RE**TE*2244558

PO1*01*90*CA*200**UA*12345679124*IN*COSTCO'S ITEM NUMBER

PID*F****VIM DETERGENT

SAC*C*ZZZZ***10*******06***CHARGE DESCRIPTION

SDQ*EA*92*0008*50*0020*10*0023*10*0024*15*0025*05

PO1*02*90*CA*200**UI*12345679125*IN*COSTCO'S ITEM NUMBER

PID*F****ICI SNOWSAME EXTERIOR PAINT

SAC*C*ZZZZ***10*******06***CHARGE DESCRIPTION

SDQ*EA*92*0008*50*0020*20*0023*20

PO1*03*90*CA*200**UP*12345679126*IN*COSTCO'S ITEM NUMBER

PID*F****ICI SNOWSAME EXTERIOR PAINT

SAC*C*ZZZZ***10*******06***CHARGE DESCRIPTION

CTT*3*270

SE*38*0001

GE*1*1

IEA*1*000000001.

There are many more types of dispatch requirement. For further queries, mail me at ambarnath@crossroadtechnologies.in

Tuesday, December 30, 2008

Classified POs in EDI

An EDI 850 Purchase Order is an electronic version of a paper Purchase Order, generally referred as “PO”. Companies use EDI to reduce the errors and costs associated with the manual keying of data, and to speed up the process of sending and receiving Purchase Orders. A buyer will use the 850 Purchase Order to communicate to a supplier the specific items, price, and quantities they wish to have delivered.

One of the important aspects of PO is the different types of Purchase Orders which is passed through the BEG02 Segment of 850 EDI data transmission depending upon the customer’s requirement. This topic is put up to throw some light on the Purchase Order Type Codes.

Standalone [SA]: A discrete, one-time commitment to a supplier for material.

Rush Order [RO]: Requisition requiring issuance of a Purchase Order in less than 5 days. In order to avoid costly disruption of pre-planned programs, or to eliminate a significant safety or security problem, order must be accompanied by the Purchasers, justifying explanation. Here invoice can be sent after some time but the delivery should happen immediately. Generally this happens in the festive seasons.

Blanket order [BE] / [BK]: A blanket order is defined as an order the customer negotiates with its supplier. This order contains multiple delivery dates scheduled over a period of time for specific goods, sometimes at predetermined prices. It is normally used when there is a recurring need for expendable goods. Hence, items are purchased under a single purchase order rather than processing a separate P.O. each time new supplies is effected.

Types of Blanket Order

There are two types of Blanket Orders, one with firm quantity and the other with Estimated quantity.

Blanket order (firm quantity)[BK]: The Type Code of "BK" will identify a bulk Purchase Order, with store/quantity allocations. The same purchase order number in the bulk "BK" order will be transmitted in the release "RL" order.

Blanket order (Estimated quantity)[BE]: The Type Code of "BE" will identify a bulk Purchase Order, without store/quantity allocations ie Not Firm Commitment. The same purchase order number in the bulk "BK" order will be transmitted in the release "RL" order.

Advantages of Blanket Orders

For the customers, negotiating a blanket order will dispense him from holding large inventories of goods, while letting him avoid the administrative expense of processing frequent purchase orders. Also, it will often give him access to favorable discount pricing through volume commitments.

As for supplier, the advantage in signing blanket orders include better management of its own supplies, as well as better planning of delivery and production cycles. Also, signing blanket orders can ensure a steady workflow, rather than producing / supplying large quantities of products at irregular intervals.

Usage of Blanket Orders

Blanket purchase orders should be used when

• There is repetitive purchase of specific goods and service from the same supplier, which are paid in a predictable manner.

• Orders require numerous shipment / excessive storage.

• Enable the purchaser to obtain favorable pricing through volume discount.

• Supports a long-term relationship between the purchaser and the supplier.

Blanket purchase orders generally should not be used when

• No benefits will be derived over use of a regular Purchase Order (i.e. volume discount).

• Quality of services and goods supplied by vendor are questionable.

• No relationships exist between the purchaser and the supplier

Content of a Blanket Order

Blanket orders format usually include the following information:

• The beginning and ending time period for the blanket order;

• A cancellation clause;

• Items and/or categories of items to be covered by the blanket purchase order;

• The estimated quantity including a maximum (if any);

• Prices and pricing arrangements;

• Terms and billing arrangements;

• Personnel authorized to issue order releases;

Release Order [RL]: An order for goods and services placed against a pre-existing contract or blanket order The Type Code of "RL" will identify a release of a bulk order, with the store/quantity allocations transmitted in the SDQ segment. The same purchase order number transmitted in the bulk "BK" order will be transmitted in the release "RL" order.

Dropship [DS]: Dropshipping is a very common phenomenon in the Retail Industry. It gained popularity for its usefulness and commercial viability. We will discuss about it and also how should do we handle it in EDI ANSI X12.

What is Dropshipping And How Does it Work?

Drop-shipping means shipping products from a wholesale supplier directly to your retail customer. In other words, you sell products in your online store, and ship the goods to your customers directly from the warehouse of your drop-ship wholesale supplier.

Why would you want to do this? Well, you only BUY a product after you already SOLD it to your customer. There's no risk of having piles of unwanted stock in your inventory.

And if you've ever sold anything and sent the products to your customers, you'll know there's a lot of time, effort, and costs involved in packing and shipping things. When you're drop-shipping, the drop-ship supplier takes care of all that for you.

Won't the customers just go direct to my wholesaler and not buy from me any more?

With a good drop-shipper, your customer only has contact with you, not with the supplier. The wholesale products will be sent "blind" by the supplier so that your customers cannot trace the name and address of the drop-ship source.

Why Consider Drop Ship Wholesale Sourcing?

• You can start a business selling products without a large initial investment;

• You don't have to buy electronics in bulk - just order after you get paid by your customers;

• You can 'stock' your online shop with a huge range of the latest products;

• All the item descriptions and pictures, you can just copy from your supplier;

• You can list items for sale, and if they aren't popular, you didn't lose anything;

• No warehouse costs and no risk of 'dead' stock;

• You don't have to worry about packing materials, shipping labels, paying couriers for delivery, or customising the product contents for different regions;

• You can sell and ship to customers anywhere in the world;

• You set your own prices and profit every time you sell something!

Who can avail the benefit of Drop-ship Selling ?

• Anyone who wants to start a home based business

• Anyone who wants to start an online business

• Anyone who has an eBay business

• Anyone who doesn't want to hold inventory

• Anyone who doesn't like overhead costs

Benefits which can be derived from Drop ship consignment

• Eliminates cost of faxing, mailing, or overnighting packing slips

• Eliminates hard copy printing

• Increases availability and accuracy of up-to-date order status, shipping, and invoice information

• Improves customer service

• Reduces labor requirements

• Supports a broader selection of merchandise without additional inventory costs

• Enables faster revenue recognition

• Enhances revenue generation by extending peak/holiday selling seasons

• Improves supplier management

Direct ship—direct shipping [DR] and drop shipping are two terms generally used interchangeably. They describe a process whereby three parties interact with the sales transaction (the buyer, the seller, and the supplier). The buyer initiates a purchase from the seller who then arranges with the supplier to ship the product directly to the seller. The seller does not carry inventory of the product and the supplier does not have any direct communication with the buyer. The buyer pays the seller and the seller pays the supplier. Though both terms (direct ship and drop ship) are generally used to describe the same process, I've always considered a small distinction between the two that relates two where you are in the supply chain. To the seller, direct shipping describes both the process and an inventory/sales strategy, however, the supplier will frequently just use the term "drop ship" to describe the process whereby he is shipping the product to an address other than that of his customer (the business that is paying him for the product). Sometimes the term drop ship also describes the process of shipping to any location that is different from the customer's normal shipping location. This subtle distinction is sometimes evident in the terminology used in software documentation.

There are many more types of POs passed through BEG02, like, New Order [NE], Special Order [OS], Reorder [RE] etc which are also commonly used.

For any other info, mail me at madhurima@crossroadtechnologies.in

Monday, December 29, 2008

Importance and transmission process of Packing details

In the retail industry packaging plays a key role in the business transaction. Product gets packed in intricate packaging process to facilitate logistic and customers’ ease of operation. This has to be passed properly through EDI segments in various documents to transmit properly between the Trading Partners. A few technical jargons are used to handle the packaging scenario and also used in EDI transaction. A brief discussion is presented below.

Most commonly used terms are :

Pack: The purchased unit which contains a specified quantity.

Pack ID: A unique alpha numeric code provided by the Vendor to represent a unique Case Pack

Inner Pack: A packing unit inside a Pack.

Inner Pack ID: A unique number that represents the packing unit inside a Pack.

Pack and Inner Pack related data transmission:

The PO4 Segment is used to transmit information about the packaging of the product being ordered in the case or carton. Two level of packaging may be specified. The first level, specified using PO401(Pack) which is Data Element 365, may be actual items, e.g., consumer units or may be the number of smaller containers within the case. The second level , specified using PO414(Inner Pack) which is Data Element 810 , is the number of eaches in each inner container when Data Element 356 is the number of smaller containers within the case.

Variation of Data Element Definition:

As defined in 3070

Data Element 356 : Pack-Number of inner pack units per outer pack unit

Data Element 810 : Inner Pack- Number of units in each selling pack or inner item

As defined in 4010

Data Element 356 : Pack-Number of inner containers, or numbers of each if there are no inner containers, per outer container.

Data Element 810 : Inner Pack- Number of eaches per inner container. Data Elements 356 and 810 (Pack) may be used to specify the packaging of the items in the case or carton.

Example A: No inner pack , ordering quantities specified in the cases.

In the Purchase Order, the item U.P.C . is specified and the unit of measure is Case. Data Element 356 is used and Data Element 810 is not used. The absence of Data Elements 810 indicates that the inner packs are not used.

VICS EDI example

Data Element Value

PO102 20

PO103 CA

PO401 10

PO414 Not Used

The total number of cases ordered is 20. The total number of eaches ordered is 150, case quantity ordered multiplied by Pack quantity (20*10=200)

Example B: No inner pack, ordering quantities specifics are in Eaches:

In the Purchase Order, the item U.P.C . is specified and the unit of measure is Each. Data Element 356 is used and Data Element 810 is not used. The absence of Data Element 810 indicates that inner packs are not present.

VICS EDI example

Data Element Value

PO102 20

PO103 EA

PO401 10

PO414 Not Used

The total number of eaches ordered is 200. The total number of cases ordered is 10, eaches quantity ordered divided by Pack quantity (200/10=20).

Example C: Inner Packs, ordering quantities specified in Cases:

In the Purchase Order, the items U.P.C. is specified and the unit of measure is Case. Data Element 356 and 810 are both used. The presence of Data Element 810 indicates that the inner packs are used, i.e., each case contains 6 small containers and each smaller container contains 4 of the units specified by the item U.P.C.

VICS EDI example

Data Element Value

PO102 10

PO103 CA

PO401 6

PO414 4

The total number of cases ordered is 10. The total number of eaches ordered is 240, case quantity ordered multiplied by the product of Pack quantity and Inner Pack quantity (10*(6*4)=240).

Example D: Inner Packs, ordering quantities specified in Eaches:

In the Purchase Order, the items U.P.C. is specified and the unit of measure is Each. Data Element 356 and 810 are both used. The presence of Data Element 810 indicates that the inner packs are used, i.e., each case contains 6 small containers and each smaller container contains 4 of the units specified by the item U.P.C.

VICS EDI example

Data Element Value

PO102 240

PO103 EA

PO401 6

PO414 4

The total number of eaches ordered is 240.The total number of cases ordered is 10, eaches quantity ordered divided by the product of Pack quantity and Inner Pack quantity (240/(6*4)=10).

Live Scenarios of usage of Pack/Inner Pack

Example 1: No inner Pack

Household cleaning product is the item in the example, packed 12 to a case. The shipping container is marked with a case U.P.C. and the items is marked with the consumer U.P.C. The product size is 5 ounces

Example 2: Simple Inner Packs

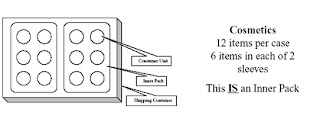

Cosmetic is the item in this example. The product is shipped using inner containers. There are 2 inner containers per shipping container and each inner container holds 6 consumer units. The shipping container is marked with a case U.P.C., the inner containers are not marked with any U.P.C. marking, and the item is marked with the consumer U.P.C. The product size is 3 ounces.

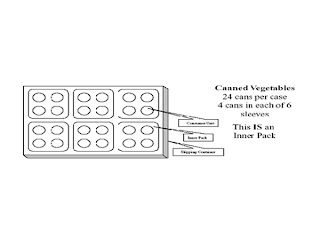

Example 3: Complex Inner Packs

Canned Vegetable is the item in the example. The product is shipped using inner containers. There are 6 inner containers per shipping containers and each inner containers holds 4 consumer units. The shipping container is marked with a case U.P.C., the inner containers are marked with a consumer U.P.C.(U.P.C.1 → considered as saleable item), and the item is marked with the consumer U.P.C. .(U.P.C.2 → also considered as saleable item). The product size is 8 ounces.

For any query, mail me at :

madhurima@crossroadtechnologies.in

Subscribe to:

Comments (Atom)